Samach: Furnishing Woodworking Machines Experts

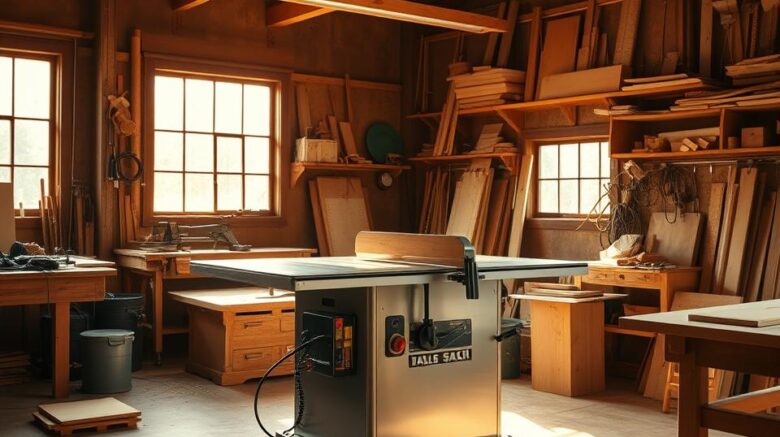

Have you ever questioned what it requires to transform unrefined materials into premium final goods? The solution resides in exactness, ingenuity, and the correct tools. Samach is at the vanguard of this market, providing trusted solutions for contemporary fabrication demands.

Backed by decades of knowledge, Samach has become a top brand in the field. Their cutting-edge woodworking machine are designed to deliver unmatched accuracy and efficiency. Whether you are a specialist or a beginner, their innovations ensures every assignment satisfies the most rigorous benchmarks.

Spanning state-of-the-art apparatus and steadfast backing, Samach provides a complete range to excel. Explore further details on their innovative solutions by navigating to www.samach.cn. This article will take you through the essential aspects of their offerings, helping you make informed decisions for your endeavors.

Introduction to Samach and Furniture Woodworking Machinery

Accuracy and creativity are the pillars of modern production, and Samach shines in providing both. With decades of experience, Samach has grown into a dependable moniker in the carpentry sector, providing cutting-edge approaches for both specialists and amateurs.

Samach’s expertise lies in combining classic workmanship with cutting-edge technology. Their woodcraft devices are engineered for the strictest criteria of accuracy and efficiency. Whether you’re working on small projects or large-scale production, Samach delivers the equipment essential for achievement.

Our Story and Samach’s Mastery

Samach’s journey began with a focus on quality and innovation. Currently, they stand as an international frontrunner in the woodworking machinery sector. Their group of specialists ensures every product is built to last, offering reliability and performance that professionals trust.

Ranging from CNC routers to edgebanders, Samach’s lineup serves multiple demands. Their machines are designed to manage complex tasks with ease, establishing them as a prime option in the woodworking industry.

Web Address and Reliable Offerings

For more information on Samach’s innovative solutions, visit www.samach.cn. Their website offers detailed insights into their lineup, service offerings, and worldwide showrooms. Samach’s dedication to quality renders them a dependable associate for specialists around the world.

| Feature | Parameter |

|---|---|

| RPM Spectrum | 12K to 18K r/min |

| Operational Speed Span | 1 up to 15 m/min |

| Top Cutting Capacity | 3100 mm |

| Primary Saw Engine Output | 5.5KW |

| Assurance Term | 12 Months |

Samach’s machines are backed by industry-leading warranties and ISO 9001 certification. Their worldwide reach covers regions including Vietnam, Brazil, and South Korea, ensuring accessibility for customers worldwide.

Steering Through Woodworking Apparatus

Ranging from hand-operated devices to sophisticated systems, woodcraft equipment present varied answers for every project. Be you an expert or a novice, grasping the contrasts between hand-operated and automated systems is vital for achievement.

Comparative Look at Hand-operated and Automated Equipment

Manual machines, like wood lathes, require hands-on control and are ideal for smaller, detailed tasks. They deliver accuracy yet require additional time and labor. Conversely, automated systems like CNC machines optimize manufacturing with limited manual input. These are perfect for large-scale projects and complex designs.

Primary distinctions are:

- Manual machines are cost-effective but slower.

- Robotic systems boost productivity and uniformity.

- Both types cater to different needs in the woodworking industry.

Essential Attributes and Advantages for Carpenters

High-quality machines are defined by their precision, ease of use, and ability to handle various materials. Advanced technology ensures consistent results, even with solid wood. For example, CNC machines offer unmatched accuracy, while wide belt sanders provide smooth finishes.

Gains involve:

- Improved productivity and reduced waste.

- Augmented protective features for operators.

- Versatility in meeting shifting project needs.

The carpentry sector persistently adopts novel materials and modern tech, rendering current equipment more dependable and effective than before.

Buyer’s Guide to Top Woodworking Equipment for Furniture Making

Choosing the right equipment is the first step toward achieving flawless results in any project. Be it constructing cabinets or managing intricate layouts, the instruments employed can transform your output. This overview will help you understand the types of equipment available and methods to assess their caliber for your requirements.

Comprehending Various Tool Categories

Ranging from surface planers to joinery apparatus, a broad spectrum of equipment is tailored for distinct jobs. Every category fulfills a specific role in manufacturing. As an example, planers are perfect for flattening surfaces, whereas joinery tools secure exact bonds between components.

Below is a brief summary of typical tool categories:

- Planing Machines: Ideal for evening and refining textures.

- Joinery Equipment: Guarantees precise and long-lasting bonds.

- CNC Machines: Perfect for complex patterns and extensive manufacturing.

Measuring the Caliber of Machinery

Selecting high-quality machinery is crucial for consistent results. Identify traits including longevity, accuracy, and straightforward maintenance. Durable machinery improves output while cutting back on maintenance intervals and repair expenditures.

Here are key criteria to consider:

- Durability: Check the build quality and materials used.

- Accuracy: Confirm that the device produces exact performance reliably.

- Maintenance Friendliness: Opt for equipment that’s easy to clean and repair.

Assessing these criteria helps you procure machines that satisfy your demands and offer lasting worth.

Essential Accessories and Technological Advances

In today’s dynamic production environment, add-ons and innovation are fundamental to improving output. From innovative belting solutions to advanced automated systems, these components are transforming how machines operate. This portion delves into the revolutionary innovations defining upcoming manufacturing trends.

Innovative Belting Solutions and Edge Banding

Belting methods such as trailroll belts and sandbelts are transforming precision in machinery. These accessories ensure smooth operations, especially in tasks like edge banding. Edge banding accessories, in particular, provide precise finishes, making them indispensable for high-quality production.

Specialized feed systems and metal components further enhance durability. As an illustration, rubber and metal rollers are vital for smoothing and fine-tuning equipment. Such components maintain uniform functionality, regardless of challenging settings.

Leveraging CNC, Lathes, and Other Tech

Computerized numerical control systems and lathes lead the wave of modern innovations. CNC systems automate complex tasks, reducing manual labor and increasing precision. Conversely, lathes are vital for crafting consistent parts, thereby improving both aesthetics and performance.

Such systems combine effortlessly with other parts, ensuring optimal processing of every item. Ranging from surface planers to brushing devices, every component aids in an efficient manufacturing flow. This culminates in remarkable gains in both excellence and productivity.

By embracing these innovations, production processes become more reliable and efficient. Whether through cutting-edge belt methods or automated apparatus, technological advances constantly redefine potential.

Industry Shifts and Technological Breakthroughs in Carpentry Equipment

The woodworking machinery sector is undergoing significant transformations driven by technology and market demands. Boasting a worldwide value of USD 4.86 billion in 2023, projections indicate growth to USD 7.77 billion by 2032. This growth is fueled by advancements in machines and the increasing adoption of innovative materials.

Effects of Worldwide Market Changes and the COVID-19 Crisis

The COVID-19 outbreak momentarily interrupted manufacturing and commerce, leading to supply chain setbacks. Nonetheless, the sector swiftly adjusted by adopting digital innovations and intelligent production systems. For example, companies like SCM Group enhanced their service offerings to meet evolving customer needs.

International market trends have likewise impacted the need for woodworking machinery. Europe, commanding a 40.53% share in 2023, remains at the forefront thanks to its emphasis on sustainability. Meanwhile, the Asia-Pacific region is expected to exhibit the highest growth rate, driven by population growth and rising disposable incomes.

Technological Progress and Forward Projections

Technological advancements are shaping the future of the industry. Automated CNC systems and machines are setting the norm by providing exactness and effective operation. These innovations are particularly beneficial for large-scale production and complex projects.

Emerging substances like Cross-Laminated Timbers (CLTs) are becoming increasingly favored. They are both eco-friendly and capable of improving the longevity and performance of products. As a result, manufacturers are investing in machinery that can handle these advanced materials.

| Market Trend | Impact |

|---|---|

| Adoption of CNC Technology | Increased precision and efficiency |

| Increase in Green Materials | Improved longevity of products |

| Expansion in the Asia-Pacific Area | Broadened commercial prospects |

Looking ahead, the industry is poised for further innovation. Customer demands for customization and sustainability will continue to drive advancements. Leveraging these developments allows companies to keep pace and address the challenges of a dynamic marketplace.

Optimizing Production with Precision and Industrial Solutions

Efficiency and accuracy are the driving forces behind modern production lines. For reliable outcomes, producers depend on state-of-the-art machines and exacting methods. This part explores how integrating cutting-edge solutions can streamline operations and elevate product quality.

Precision Milling, Edgebanding, and Cabinet Making

Precision milling is essential for creating intricate designs and ensuring uniformity in every piece. Advanced CNC systems automate this process, reducing errors and enhancing speed. Such machines are especially important in cabinet fabrication, where precision is paramount.

Trim application, a further key operation, secures flawless outcomes and resilience. Contemporary edge banding equipment incorporates custom feed mechanisms for steady performance. This method is critical for top-tier production, particularly for personalized assignments.

When constructing cabinets, meticulous instruments like CNC routers and assembly machines make a significant impact. They manage intricate blueprints effortlessly, guaranteeing each element aligns flawlessly. This level of accuracy minimizes waste and maximizes efficiency.

Strategies for Enhanced Production

Combining meticulous elements with sophisticated feed systems can greatly optimize production routines. They guarantee seamless functioning and cut back on idle periods. For example, automated feed systems maintain consistent material flow, enhancing overall efficiency.

Alternatively, utilizing modern machines for recurring assignments which not only speeds up production but also ensures uniformity across all pieces. Automating operations allows companies to direct efforts toward maintaining quality and fostering innovation.

Importance of Exactness in Ensuring Quality

Precision is the cornerstone of quality assurance in manufacturing. Advanced machines ensure every cut, drill, and finish meets exact specifications. This degree of exactness is essential to uphold lofty standards and consumer anticipations.

As an illustration, CNC technologies permit precise programming, guaranteeing optimal processing of every piece. This minimizes mistakes and bolsters the end product’s strength and performance. These exact instruments reduce resource wastage, thereby cutting costs.

Integrating exact methods with state-of-the-art tech allows companies to streamline their production systems. This approach enhances operational output while assuring that every task reaches premium standards.

Last Considerations and Forward Moves for Woodworking Perfection

Reaching peak quality in manufacturing demands proper equipment, accuracy, and an innovative mindset. In this piece, we examined how cutting-edge machines and modern strategies can reshape your tasks. From CNC systems to specialized equipment, the right tools ensure efficiency and quality.

For your next move, think about incorporating premium machines into your operations. Visit www.samach.cn to explore tailored solutions and expert support. Their focus on precision and consistent performance establishes them as a reputable collaborator in the market.

Embrace the latest advancements and align your project goals with cutting-edge technology. By focusing on continuous improvement and leveraging the right service, you can achieve outstanding results. Let innovation drive your success and elevate your production to new heights.