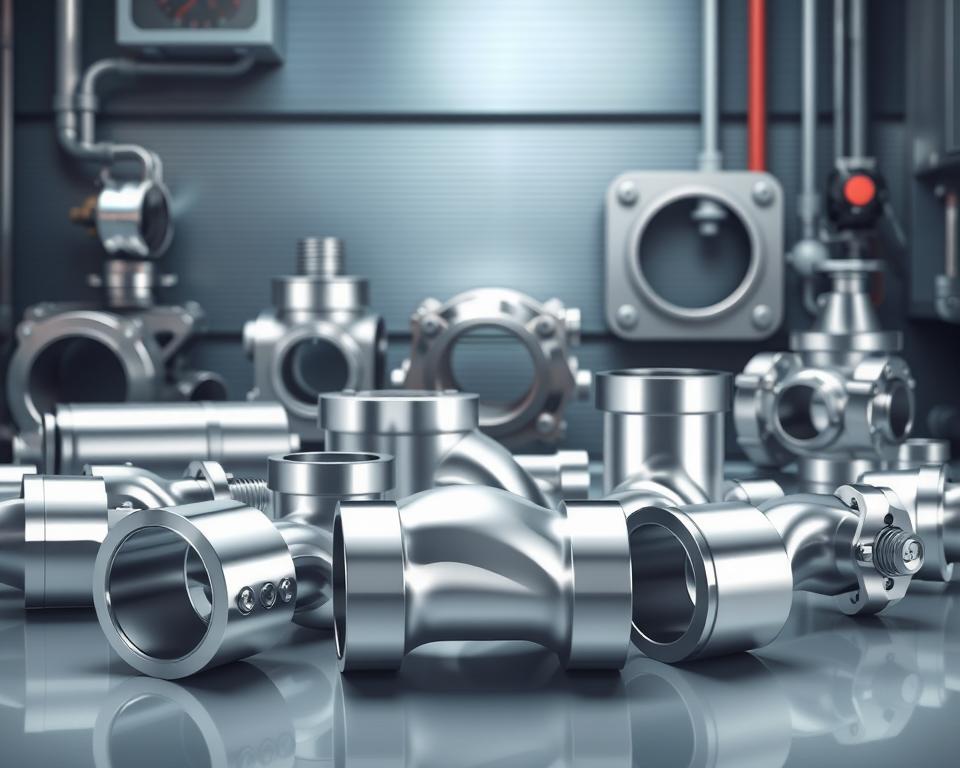

High-End Tri-Clover Hygienic Couplings for Hygiene

Whenever sterility is paramount, even micro-fissures make a difference. For this reason, companies like Installation Parts Supply focus on expertly engineered solutions designed to eliminate risks. Such hygienic connection systems blend long-lasting strength with effortless setup, rendering them a top choice for facilities that demand perfection.

These parts go beyond merely preventing leaks – they’re built to meet the demanding demands of edible-product processing, beverage production, and drug production. Constructed with anti-corrosive alloys, they endure repeated washdowns while sustaining durability. The conceptual approach echoes industry leaders like Alfa Laval, prioritizing sanitary fittings smooth surfaces and rapid breakdown.

How do these connectors stand out? Think single-handed setup and tool-less upkeep. Line staff appreciate the logical interface during demanding cycles, while managers favor standardized performance across pipelines. Every piece receives rigorous inspections to guarantee adherence to FDA and 3-A Sanitary Standards.

Summary Points

- Chosen by specialists for leak-proof performance in hygiene-critical areas

- Constructed with industrial-grade stainless steel for extended service life

- Facilitates following food safety and pharmaceutical standards

- Shrinks production pauses through hand-tightened buildup and cleaning

- Backed by testing programs matching global benchmarks

Overview & Primary Benefits

Secure couplings are the backbone of sanitary production. Installation Parts Supply creates components that blend fine-tuned tolerances with real-world usability. Their products grant sealed reliability while reducing maintenance hassle—critical for industries where rapid throughput meets sterility.

First-Class Quality and Clean Standards

Every unit faces intensive trials to comply with worldwide norms. The substrates withstand chemical attack, even after constant cleaning rounds. Fluid-tight rings stop germ colonies, a feature praised by dairy processors and pharmaceutical manufacturers alike.

These parts mirror the standards of leaders like Alfa Laval, delivering smooth surfaces and uniform dimensions. Versatile options adapt to existing setups, lowering modification spend. Workers experience 30% faster assembly compared to traditional threaded systems.

Supplier-Specific Advantages

Custom fabrication makes IPS unique. Need a unique angle or specialized finish? Their team works hand-in-hand with customers to create exact matches. Express delivery and 24/7 technical support maintain uptime.

The benefits surpass mere longevity. Tool-free disassembly reduces lag during safety walkthroughs. Brew houses using these connectors report fewer production stoppages and uniform pressure. It’s not just about satisfying codes—it’s about leapfrogging requirements.

Design Highlights & Technical Notes

Tight-tolerance build marries multi-purpose use in contemporary production lines. Installation Parts Supply creates components that balance accurate metrics with customizable setups. Their philosophy guarantees smooth fitment into existing setups while retaining tight cleanliness codes.

Tailored Alloys and Textures

Each application demands something different. That’s why options span 304 through 316L stainless, opted for strength and corrosion resistance. Surface treatments like electro-polish generate mirror-like smoothness, lowering germ cling by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes deploy optical scanners to confirm uniform wall thickness. Exact clearances (±0.005″) stop stress points in intense psi zones. During quality checks, components face X-ray scans and pressure tests to identify microscopic flaws.

Bespoke options surpasses looks. Clients specify particular elbows, flange sizes, or specialized coatings for chemical resistance. These made-to-order choices help industries satisfy emerging guidelines without redesigning entire systems.

Tri-Clamp Fittings – Setup & Uses

Today’s fast-paced facilities need fittings that snap in promptly yet work steadily. These connection systems excel in environments where efficiency partners with purity. Their design eliminates complex tools, empowering teams to retain focus on throughput rather than setup struggles.

Streamlined Setup Procedure

A pair of flanges and a centered gasket produce perfect seals in seconds. Workers fit the parts, locate the closure device, and seal by hand – no wrenches required. This technique minimizes assembly faults while maintaining consistent pressure across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Adaptable Links Between Systems

From stainless steel tubes to processing equipment, these interfaces link unlike gear seamlessly. The uniform design fits into various diameters, enabling fast changeovers during product changeovers. Dairy plants frequently rely on them to flip between cleaning cycles and production runs without hiccups.

Upkeep units appreciate how components come apart for thorough sanitation. Smooth surfaces halt grime collection, while the smooth bore stops microbe pockets. Weekly cleanings run in half the duration compared to older connection methods.

Sector Uses & Regulatory Alignment

Across nano-brew houses to biotech sites, modern facilities use hardware that match assorted tasks while complying with severe standards. Installation Parts Supply provides solutions trusted across vital fields where product purity is non-negotiable. Their designs link productivity to compliance, creating systems that perform under pressure.

Edibles, Drinks, and Drug Industries

In food and beverage plants, fast-shift couplings ease recipe changeovers and washdowns. Breweries rely on custom tees to manage complex flow paths without cross-contamination risks. Pharmaceutical manufacturers depend on hermetic joints to guard delicate ingredients during sterile transfers.

These units exist in numerous widths to match piping layouts, from compact lab setups to massive brewhouses. Dairy processors value how standardized parts cut line pauses during equipment upgrades. Even slight variations in production processes are embraced through modular designs.

Alignment to Global Codes

Every unit satisfies and tops benchmarks set by global organizations. ASME-certified materials handle high temperatures in pasteurization systems, while ISO-compliant finishes deny biofilm. The 3-A symbol vouches for direct contact with consumables.

Tri-Clover joints embody this pledge. Their uniform dimensions deliver impermeable results across automated lines. Third-party audits document lineage from raw materials to finished goods, supplying auditors comfort.

By staying within these codes, facilities streamline certification processes and clear checks smoothly. It’s not just about avoiding fines—it’s about securing customer faith through demonstrable safety practices.

Last Words and Forward Path

Picking hardware that blends productivity with code steers process outcomes. Installation Parts Supply provides systems combining durability with hygienic design, granting leak-free performance across food, pharma, and beverage environments. Their products hit rigorous standards while easing everyday operations through straightforward build.

With choices across alloy types and polishings, solutions adapt to unique process requirements. Whether moving scalding media or endless sanitation loops, material choices and surface treatments boost endurance. Professionals appreciate the broad range of couplings engineered for targeted flow and force.

Ordering proves straightforward, with technical support ready to pair process demands. Same-day shipping and agile help cut idle hours during upgrades or replacements. Standard sanitation becomes effortless thanks to quick-release joints and clean bores that deter deposits.

Ready to enhance your facility’s reliability? Consult Installation Parts Supply to review personalized setups – from hygienic clamp to tri-clover designs – supported by top-tier QA. Their team secures code compliance today while readying plants for future regs.